Permalloy Alloy 80(1J79) /UNS N14080,GB/T 32286.1-2015 Bar Tube Pipe Wire

Overview

1J79 is a nickel-ferromagnetic alloy with a nickel content of about 80% and an iron content of about 20%. In 1914, Gustav Ehrmann, a physicist at Bell Telephone Laboratories, invented the alloy. Due to its high magnetic permeability, 1J79 is widely used as a magnetic core material for electrical and electronic devices, as well as a magnetic shielding material for shielding magnetic fields.

In commercial permalloy, its relative permeability is usually around 100,000, while the relative permeability of ordinary steel is only thousands. In addition to high permeability, 1J79 has other magnetic properties such as low coercivity, near zero magnetostriction, and significant anisotropic magnetoresistance. Low magnetostriction is very important for industrial applications because it allows 1J79 to be used in thin films that would otherwise result in large changes in magnetic properties under variable stress.

At 80% nickel concentration, Permalloy typically has a face-centered cubic crystal structure with a lattice constant of about 0.355 nm. However, one disadvantage of Permalloy is that it is not very malleable, so for applications requiring complex shapes, such as magnetic shielding, it is often made of other alloys with high magnetic conductivity, such as mu metal.

Nevertheless, 1J79 is still widely used in transformer pieces and magnetic recording heads. In addition, 1J79 is also widely used in the radio electronics industry, precision instruments, remote control and automatic control systems and other fields.

Limiting Chemical Composition, %

Nickel...................................................................................................................................................................................78.50-80.00

Molybdenum............................................................................................................................................................................3.80-4.10

Manganese..............................................................................................................................................................................0.60-1.10

Carbon......................................................................................................................................................................................0.03 max.

Copper......................................................................................................................................................................................0.20 max.

Iron........................................................................................................................................................................................13.03-16.60

Phosphorous............................................................................................................................................................................0.02 max.

Silicon.......................................................................................................................................................................................0.30-0.50

Sulfur.........................................................................................................................................................................................0.02 max.

Physical Constants

Density |

g/cm^3.................................................................................................8.6 |

Electrical resistivity |

at 20℃(Ωmm2/m)............................................................................0.55 |

Coefficient of linear expansion |

(20℃~200℃)X10-6/℃............................................................10.3-11.5 |

Saturation magnetostriction coefficient |

λθ/ 10-6...............................................................................................2.0 |

Curie point |

Tc/ ℃..................................................................................................450 |

Tensile Properties

Yield strength (MPa) |

Tensile Strength (MPa) |

Elongation A % |

150-980 |

560-1030 |

3-50 |

Heat treatment

Intermediate annealing: In order to eliminate all strain and return the alloy to a soft state suitable for further cold rolling or drawing, forming, bending or similar operations, annealing at 1020 to 1080 ° C for no more than 1 hour. Because high-nickel, high-permeability alloys readily absorb carbon, sulfur, oxygen, and other contaminants from combustion furnace gases, annealing should be carried out in dissociated ammonia, hydrogen, vacuum, or inert gas atmospheres during the process.

Final annealing: In order to obtain maximum softness and best magnetoelectric properties, the cold-deformed 1J79 alloy should be annealed at 1180 ° C for 3 to 5 hours in an oxygen-free dry hydrogen atmosphere with a dew point below -40 ° C, and then tempered.

Oil, grease, paint and all other contaminants must be removed before annealing. During hydrogen annealing, the individual parts should be separated by inert insulating powders such as magnesium and alumina.

Vacuum heat treatment can be used, but it usually results in a loss of magnetism compared to heat treatment in a dry hydrogen atmosphere.

Available Forms

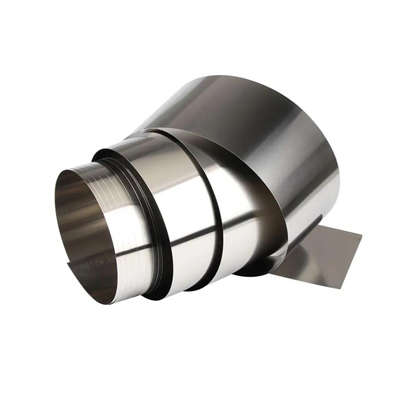

● Strips & Tape

● Wire & Welding

● Pipe & Tube

● Sheet & Foils

● Flanges & Forgins

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder