ЭИ435,Nimonic 75/UNS N06075/W.Nr. 2.4951 &2.4630 bar, sheet , wire,strip

Overview

NIMONIC alloy 75 (UNS N06075/W.Nr. 2.4951 &2.4630) is an 80/20 nickel-chromium alloy with controlled additions of titanium and carbon.

Nimonic 75 is a nickel-chromium alloy that has gained widespread use in the industry due to its unique properties. It has excellent mechanical and physical properties, including high-temperature resistance, corrosion resistance, and impressive tensile strength.

It has many applications, including in the aerospace, petrochemical, and power generation industries. Overall, Nimonic 75 is a high-performance alloy sought-after material in various industries.

Limiting Chemical Composition, %

Nickel........................................................................................................................................................................................Balance.

Carbon ..................................................................................................................................................................................0.08-0.150

Copper.......................................................................................................................................................................................0.5 max.

Iron...........................................................................................................................................................................................5.00 max.

Manganese..............................................................................................................................................................................1.00 max.

Silicon......................................................................................................................................................................................1.00 max.

Titanium...................................................................................................................................................................................0.20-0.60

Physical Constants

Density |

Mg/m3............................................................................................8.37 |

lb/in3.............................................................................................0.302 |

|

Melting Range |

°C.........................................................................................1340-1380 |

°F...........................................................................................2450-2520 |

Mechanical properties

Properties |

Metric |

Imperial |

Tensile strength(annealed) |

750 MPa |

109 ksi |

Yield strength(annealed) |

275 MPa |

40 ksi |

Elongation at Break |

42% |

42% |

Modulus of Elasticity |

206 GPa |

29878 ksi |

Corrosion Resistance

Nimonic 75 has excellent resistance to corrosion and oxidation. This makes it an ideal choice for applications where exposure to high temperatures and reactive environments is a concern. The alloy is particularly useful in aircraft and maritime applications.

Heat Treatment

For bar products, heat for 30-60 minutes to 1050°C (1920°F) followed by air cooling.

For sheet products, 5-10 minutes at 1050°C F (1920°F) followed by air cooling, or, before welding, 5-10 minutes at 1050°C (1920°F) and air cool, plus an optional 10 minutes at the same temperature followed by air cooling.

WELDING

Alloy 75 should preferably be welded in the annealed condition, and post-weld treatment is not normally necessary unless corrosion conditions are severe. MMA, TIG, MIG and submerged-arc processes may be used, as may electron beam, oxy-acetylene and resistance welding.

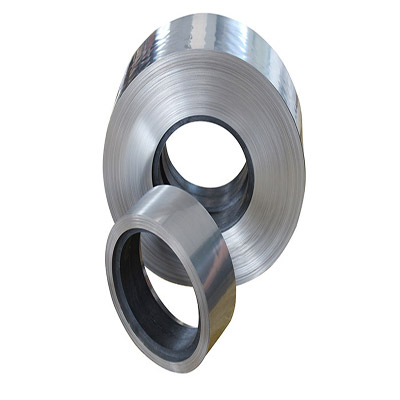

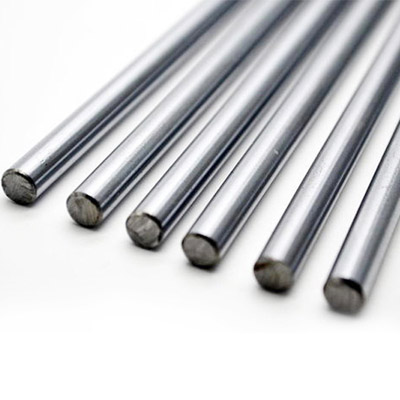

Available Forms

● Strips & Tape

● Wire & Welding

● Pipe & Tube

● Sheet & Foils

● Flanges & Forgins

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder