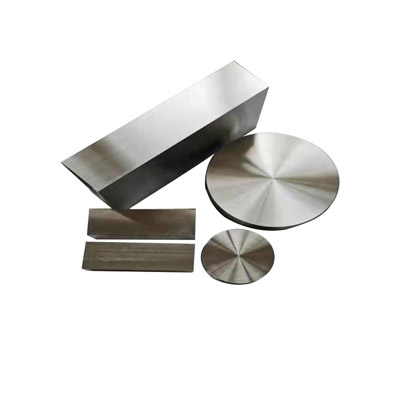

Monel 400 UNS N04400/W.Nr.2.4360 ASTM B127 sheet bar ring

Overview

MONEL nickel-copper alloy 400 (UNS N04400/ W.Nr. 2.4360 and 2.4361) is a solid-solution alloy that can be hardened only by cold working. It has high strength and toughness over a wide temperature range and excellent resistance to many corrosive environments.

Alloy 400 is widely used in many fields, especially marine and chemical processing. Typical applications are valves and pumps; pump and propeller shafts; marine fixtures and fasteners; electrical and electronic components; springs; chemical processing equipment; gasoline and fresh water tanks; crude petroleum stills, process vessels and piping; boiler feedwater heaters and other heat exchangers; and deaerating heaters.

Limiting Chemical Composition,%

Nickel (plus Cobalt).................................................................................................................................................................63.0 min.

Carbon.....................................................................................................................................................................................0.30 max.

Manganese..............................................................................................................................................................................2.00 max.

Iron...........................................................................................................................................................................................2.50 max.

Sulfur......................................................................................................................................................................................0.024 max.

Silicon.......................................................................................................................................................................................0.50 max.

Copper..................................................................................................................................................................................28.00-34.00

Physical Constants

Density |

lb/in^3.............................................................................................0.318 |

g/cm^3.............................................................................................8.80 | |

Specific Heat |

Btu/lb•°F.........................................................................................0.105 |

J/kg•°C..............................................................................................440 | |

Melting Range |

°F............................................................................................2370-2460 |

°C...........................................................................................1300-1350 | |

Curie Temperature |

°F……...….....................................................................................….70-120 |

°C............…..................................................................................….21-49 | |

Modulus of Elasticity, 10^3 ksi |

Tension ............................................................................................26.0 |

Compression ...................................................................................26.0 | |

Torsion................................................................................................9.5 | |

Poisson’s Ratio................................................................................0.32 |

Mechanical properties

MONEL alloy 400 has excellent mechanical properties at subzero temperatures. Strength and hardness increase with only slight impairment of ductility or impact resistance.

The alloy does not undergo a ductile-to-brittle transition even when cooled to the temperature of liquid hydrogen.

This is in marked contrast to many ferrous materials which are brittle at low temperatures despite their increased strength.

Tensile-properties

Nominal Room-Temperature Tensile Properties of MONEL Alloy 400 | |||||||

Form and Condition |

Tenslle Strength |

Yleld Strengt (0.2%Offset |

Eongation % |

Hardness |

|||

ksi |

MPa |

ksi |

MPa |

Brinel 3000-kg) |

Rockwell B |

||

Rod and Bar |

|||||||

Annealed |

75-90 |

517-620 |

25-50 |

172-345 |

60-35 |

110-149 |

60-80 |

|

Hot-Finished (except Hexagons over 21/8 inches and Angles) |

80-110 |

552-758 |

40-100 |

276-690 |

60-30 |

140-241 |

75-100 |

|

Hot-Finished Hexagons over 21/8 inches and Angles |

75-100 |

517-690 |

30-55 |

207-379 |

50-30 |

130-184 |

72-90 |

Cold-Drawn,Stress-Relieved |

84-120 |

579-827 |

55-100 |

379-690 |

40-22 |

160-225 |

85-20C |

Plate |

|||||||

Hot-Rolled,As-Rolled |

75-95 |

517-655 |

40-75 |

276-517 |

45-30 |

125-215 |

70-96 |

Hot-Rolled,Annealed |

70-85 |

482-586 |

28-50 |

193-345 |

50-35 |

110-140 |

60-76 |

Sheet |

|||||||

Annealed |

70-85 |

482-586 |

30-45 |

207-310 |

45-35 |

一 |

65-80 |

Cold-Rolled,Hard |

100-120 |

690-827 |

90-110 |

621-758 |

15-2 |

93 min. |

|

Strip,Cold-Rolled |

|||||||

Annealed |

70-85 |

482-586 |

25-45 |

172-310 |

55-35 |

一 |

68 max. |

Spring Tempe |

100-140 |

690-965 |

90-130 |

621-896 |

15-2 |

98 min. |

|

Tube and Pipe,Seamless |

|||||||

Cold-Drawn,Annealed |

70-85 |

482-586 |

25-45 |

172-310 |

50-35 |

一 |

75 max. |

Cold-Drawn,Stress-Relieved |

85-120 |

586-827 |

55-100 |

379-690 |

35-15 |

85-100 |

|

Heat-Exchanger,Annealed |

70-85 |

482-586 |

28-45 |

193-310 |

50-35 |

一 |

75 max. |

Heat-Exchanger,Stress-Relieved |

85-105 |

586-724 |

55-90 |

379-621 |

35-15 |

85-97 |

|

Hot-Extruded |

一 |

一 |

一 |

一 |

一 |

一 |

一 |

No.1 Temper (Annealed) |

85 max |

586 max |

30-45 |

207-310 |

45-30 |

73 max. |

|

No.2 Temper (Half-Hard |

85-105 |

586-724 |

55-80 |

379-552 |

30-10 |

一 |

75-97 |

No.3 Temper (Full-Hard |

110-130 |

758-896 |

90-110 |

621-758 |

10-3 |

95-27C |

|

Wire,Cold Drawn² |

|||||||

Annealed |

70-95 |

482-655 |

30-55 |

207-379 |

45-25 |

一 |

一 |

No.1 Temper |

85-100 |

586-690 |

50-75 |

345-517 |

30-20 |

||

Quarter-Hard |

95-120 |

655-827 |

65-95 |

448-655 |

25-15 |

一 |

一 |

Half-Hard |

110-135 |

758-931 |

85-120 |

586-827 |

15-8 |

||

Three-Quarter-Hard |

125-150 |

862-1034 |

100-135 |

690-931 |

8-5 |

||

Full-Hard--Spring Temper |

145-180 |

1000-124 |

125-170 |

862-1172 |

5-2 |

||

Corrosion Resistance

MONEL alloy 400 exhibits resistance to corrosion by many reducing media. It is also generally more resistant to attack by oxidizing media than higher copper alloys. This versatility makes alloy 400 suitable for service in a variety of environments.

Alloy 400 is widely used in marine applications. While alloy 400 products exhibit very low corrosion rates in flowing seawater, stagnant conditions have been shown to induce crevice and pitting corrosion. Alloy 400 is also resistant to stress corrosion cracking and pitting in most fresh and industrial waters.

MONEL alloy 400 offers exceptional resistance to hydrofluoric acid in all concentrations up to the boiling point. It is perhaps the most resistant of all commonly used engineering alloys. Alloy 400 is also resistant to many forms of sulfuric and hydrochloric acids under reducing conditions.

Heat Treatment

1.solid solution treatment

Heating: The Monel 400 alloy is heated to a range of 980 °C to 1050 °C, and kept for a period of time, so that the various elements in the alloy are fully dissolved. This process usually needs to be carried out within a certain time frame so that the elements in the alloy can be fully diffused and evenly distributed. The specific heating time depends on the thickness of the alloy and the performance of the heating equipment.

Insulation: At the heating temperature, the alloy is kept for a certain time to ensure that the elements inside are completely dissolved and a uniform distribution is achieved. The holding time is usually 1 to 4 hours, depending on the composition of the alloy and the heating temperature.

Cooling: After the solution treatment is complete, the alloy needs to be cooled quickly to fix its tissue. Common cooling methods include water quenching or air cooling. The cooling speed will affect the properties of the alloy, so it is necessary to control the cooling speed to avoid excessive thermal stress.

2. Aging treatment

The purpose of aging treatment after solution treatment is to precipitate the phase in the alloy again to improve its mechanical properties.

The temperature of aging treatment is usually low, generally between 500 °C and 650 °C. The processing time varies depending on the desired properties and the composition of the alloy, usually ranging from tens to hundreds of hours. This process can be carried out in the air, or in a specific atmosphere or vacuum environment.

Through this heat treatment process, Monel alloy 400 alloy can obtain better corrosion resistance and high temperature strength. At the same time, attention should also be paid to controlling the various parameters of the heat treatment to obtain the best performance.

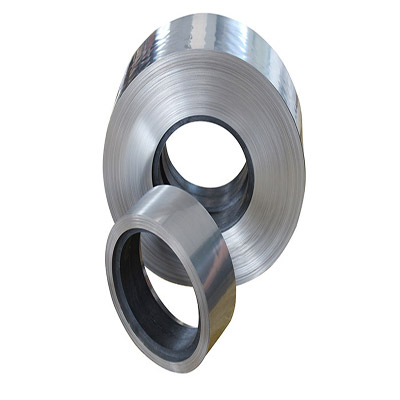

Available Forms

We provide you with a variety of product forms, including but not limited to

● Bar & Rod

● Pipe & Tube

● Coil & Strip

● Plate & Sheet & Circle

● Wire & Welding

● Fitting (Flange, Elbow, Tee...)

● Customize

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder