Hastelloy C-276 UNS N10276/W.Nr 2.4819 ASTM B575 coil bar sheet

Overview

Alloy 276 (UNS N10276) is a nickel-chromium-molybdenum alloy that has high corrosion resistance in many chemical environments. . It is one of the alloys with the strongest corrosion resistance and one of the materials with the most extensive corrosion resistance.

This alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in an as welded condition. Alloy C-276 also has excellent resistance to pitting, stress-corrosion cracking and oxidizing atmospheres up to 1900°F. Alloy C-276 has exceptional resistance to a wide variety of chemical environments.

HASTELLOY C-276 alloy is available in the form of plates, sheets, strips, billets, bars,wires, pipes, tubes, and covered electrodes. Its applicable fields include Industries such as petrochemical processing, waste gas desulfurization, pulp and paper industry, industrial waste and air pollution control.

Limiting Chemical Composition,%

Nickel.........................................................................................................................................................................................Balance

Chromium............................................................................................................................................................................14.50-16.50

Ferrom.....................................................................................................................................................................................4.00--7.00

Molybdenum.......................................................................................................................................................................15.00--17.00

Tungsten..................................................................................................................................................................................3.00--4.00

Cobalt.......................................................................................................................................................................................2.50 max.

Manganese..............................................................................................................................................................................1.00 max.

Carbon......................................................................................................................................................................................0.01 max.

Vanadium.................................................................................................................................................................................0.35 max.

Phosphorous............................................................................................................................................................................0.04 max.

Sulfur.........................................................................................................................................................................................0.03 max.

Silicon........................................................................................................................................................................................0.08 max.

Physical Constants

Below are some physical constants and thermal properties of

Density |

lbs /in³....................................................................................................................................0.321 |

g/cm³.......................................................................................................................................8.89 | |

Specific Heat |

BTU/lb-°F at 70°F...................................................................................................................0.102 |

J/kg-°C at 20°C.........................................................................................................................427 | |

Modulus of Elasticity |

psi....................................................................................................................................29.8 x 10⁶ |

GPa.........................................................................................................................................205.0 | |

Thermal Conductivity 212°F (100°C) |

BTU-in/ ft2-hr-°F.......................................................................................................................67.9 |

W/m-°C.......................................................................................................................................9.8 | |

Melting Range |

°F...................................................................................................................................2415–2500 |

°C..................................................................................................................................1325–1370 | |

Electrical Resistivity |

Microhm-in at 75°F.....................................................................................................................51 |

Microhm-cm at 24°C...............................................................................................................1.30 |

Mechanical properties

Yield Strength Ultimate Tensile Elongation Hardness 0.2% Offset |

Ultimate Tensile Elongation Hardness 0.2% Offset Strength |

Elongation Hardness 0.2% Offset Strength in 2 in. |

Hardness |

||

psi |

(MPa) |

psi |

(MPa) |

% |

(max.) |

41000 |

283 |

100000 |

690 |

40 |

100 Rockwell B |

Tensile-properties

Temperature |

Tensile strength |

||

°C |

°F |

MPa |

ksi |

20 |

68 |

310 |

45.0 |

100 |

212 |

280 |

40.6 |

200 |

392 |

240 |

34.8 |

300 |

572 |

220 |

31.9 |

400 |

752 |

195 |

28.3 |

450 |

842 |

150 |

21.8 |

Corrosion Resistance

Alloy C-276 can be used in many chemical processes with both oxidizing as well as reducing media. The high chrome and molybdenum concentrations make the alloy resistant to chloride ion attacks. The tungsten content further increases this resistance. VDM® Alloy C-276 is one of the few materials that are resistant against chlorine gas, hypochlorite and chlorine dioxide solutions. The alloy is characterized by excellent resistance against concentrated solutions of oxidizing salts (such as iron III and copper chloride).

Heat Treatment

Solution annealing should take place at temperatures of between 1,100 and 1,160 °C (2,012 and 2,120 °F). The retention

time during annealing depends on the semi-finished product thickness and can be calculated as follows:

· For thicknesses d < 10 mm (0.4 in), the retention time is t = d ∙ 3 min/mm

· For thicknesses d = 10 to 20 mm (0.4-0.8 in), the retention time is t = 30 min + (d – 10 mm) ∙ 2 min/mm

· For thicknesses of d = 20 mm (0.8 in), the retention time is t = 50 min + (d – 20 mm) ∙ 1 min/mm

Available Forms

We provide you with a variety of product forms, including but not limited to

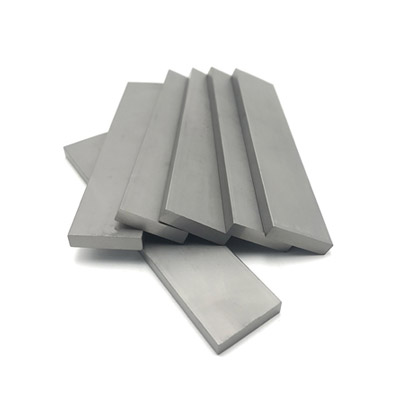

● Bar & Rod

● Pipe & Tube

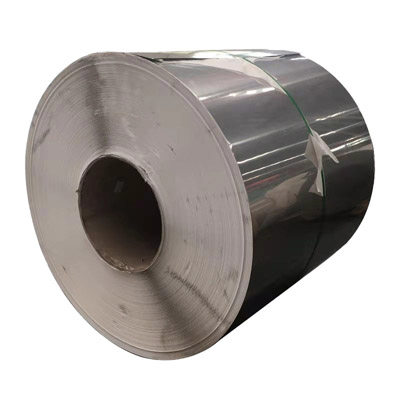

● Coil & Strip

● Plate & Sheet & Circle

● Wire & Welding

● Fitting (Flange, Elbow, Tee...)

● Customize

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder