Kovar Alloy 29 (4J29)/UNS K94610/W. Nr.1.3981 ASTM F15 Bar Sheet Strip Tube

Overview

Nilo alloy 4J29, commonly referred to as Kovar alloy, is a carefully designed and optimized nickel-iron alloy. This alloy is widely acclaimed for its unique physical and chemical properties, especially in applications where the material's coefficient of linear expansion, thermal stability and corrosion resistance are strictly required.

The main components of 4J29 alloy are iron and nickel, and a certain amount of cobalt is added to achieve the required properties. Its coefficient of linear expansion is precisely adjusted to match specific types of glass and ceramic materials, such as borosilicate glass, thus ensuring excellent sealing performance over a wide temperature range. This characteristic makes 4J29 alloy ideal for the manufacture of highly reliable electronic packages and vacuum devices.

Nilo alloy 4J29 also exhibits excellent corrosion resistance, maintaining the stability of its structure and properties even in humid, salt spray or other corrosive environments. This makes it an ideal material for equipment operating in harsh conditions, such as Marine engineering, chemical processing, and aerospace applications.

Limiting Chemical Composition, %

Iron............................................................................................................................................................................................Balance.

Nickel...................................................................................................................................................................................28.50-29.50

Cobalt..................................................................................................................................................................................16.80-17.80

Molybdenum...........................................................................................................................................................................0.20 max.

Chromium...............................................................................................................................................................................0.20 max.

Copper.....................................................................................................................................................................................0.20 max.

Silicon.....................................................................................................................................................................................0.30 max.

Manganese.............................................................................................................................................................................0.50 max.

Sulphur....................................................................................................................................................................................0.02 max.

Phosphorus............................................................................................................................................................................0.02 max.

Carbon......................................................................................................................................................................................0.03 max.

Physical Constants

Density |

lb/in^3..................................................................................0.302 |

g/cm^3...................................................................................8.36 | |

Melting Range |

°F...........................................................................................2460 |

°C..........................................................................................1450 | |

Thermal Conductivity at 20°C (68°F) |

W/m.k....................................................................................17.3 |

Mechanical Properties

Typical Mechanical Properties of Strip(Tested parallel to the direction of rolling,Material annealed 1830°F for 30 minutes, then furnaced cooled)

Yield Strength,MPa |

Tensile Strength,MPa |

% Elongation in 2" |

Hardness Rockwell B |

345 |

517 |

30 |

68 |

Magnetic Properties

Kovar alloy is magnetic at all temperatures below the Curie point. Magnetic properties will depend upon heat treatment; the lower the hardness, the higher the permeability values and lower hysteresis loss. Examples of permeability properties are shown in the following chart:

Flux Density |

1830°F (999°C) 30 min. - FC Permeability |

2010°F (1099°C) 20 min. - FC Permeability |

500 |

1000 |

1900 |

1000 |

1400 |

3500 |

2000 |

2000 |

5800 |

5000 |

2300 |

10000 |

10000 |

3400 |

8200 |

12000 |

3000 |

5000 |

Thermal Treatments

All degreased, fabricated Kovar alloy parts should be degassed and annealed in a wet hydrogen atmosphere. Atmosphere is to be made moist by bubbling the hydrogen through water at room temperature. Care must be taken to prevent surface carbon pickup. Furnace should have a cooling chamber provided with the same atmosphere. Heating should be conducted within the 1540/2010°F temperature range. Time at temperature should be approximately two hours for lowest temperature to 20 minutes for the highest temperature. Parts should then be transferred to the cooling zone and held until below 570°F, then removed. An oxide film on the metallic part is preferred for metal-to-hard glass sealing. The best oxide film is thin and tightly adhering. The film can be produced by heating the parts to 1200/1290°F in regular ambient atmosphere for a time sufficient to form a dark gray to slight brown oxide.

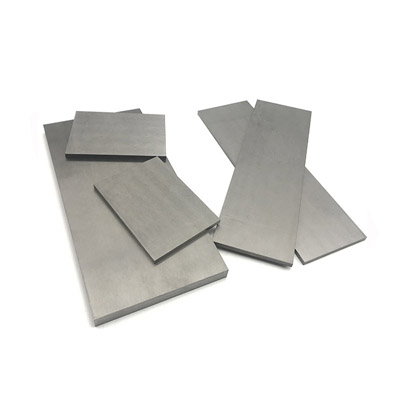

Avaliable Forms

We provide you with a variety of product forms, including but not limited to

● Bar & Rod

● Pipe & Tube

● Coil & Strip

● Plate & Sheet/Circle

● Wire

● Fitting (Flange, Elbow, Tee...)

● Customize

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder