AL-6XN UNS N08367 Stainless steel

overview

AL-6XN (UNS N08367) is a 6% molybdenum, low carbon, nitrogen-bearing super-austenitic stainless alloy. The alloy was designed to be a seawater resistant material and has been found to be resistant to a broad range of corrosive environments.

AL6XN has high nickel (24%), molybdenum (6.3%), nitrogen and chromium contents that give it excellent resistance to chloride stress corrosion cracking, chloride pitting, and exceptional general corrosion resistance.

AL6XN is primarily used for its improved pitting and crevice corrosion resistance in chlorides. It is a formable and weldable stainless steel.

Because of its nitrogen content, AL6XN has greater tensile strength than common austentitic stainlesses, while retaining high ductility and impact strength.

Due to the alloy’s corrosion resistance and high strength, AL-6XN is a better choice than conventional duplex stainless alloy and more cost effective nickel-base alloys.

Limiting Chemical Composition, %

Nickel....................................................................................................................................................................................................................23.5-25.5

Chromium.........................................................................................................................................................................................................20.00-22.00

Molybdenum.........................................................................................................................................................................................................6.00-7.00

Carbon...................................................................................................................................................................................................................0.03 max.

Nitrogen.................................................................................................................................................................................................................0.18-0.25

Manganese............................................................................................................................................................................................................2.00 max.

Silicon.....................................................................................................................................................................................................................1.00 max.

Phosphorus............................................................................................................................................................................................................0.40 max.

Sulphur....................................................................................................................................................................................................................0.03 max.

Copper.....................................................................................................................................................................................................................0.75 max.

Iron............................................................................................................................................................................................................................Balance

Physical Constants

Below are some physical constants and thermal properties of

Density |

g/cm³....................................................................................8.055 |

Melting Point |

°C..................................................................................1321-1393 |

Electrical Resistivity |

Ω⋅m............................................................................8.89 x 10^ -7 |

Mechanical properties

Alloy |

Tensile Strength Minimum (psi) |

Yield Strength Minimum 0.2% offset (psi) |

% Elongation in 2" Minimum |

AL-6XN Anneale |

112,000 |

57,000 |

44 |

Tensile-properties

Tensile Strength (ksi) |

0.2% Yield Strength (ksi) |

Elongation% in 2 inches |

104 |

46 |

30 |

Corrosion Resistance

Corrosion in the forms of pitting, crevice, and stress corrosion cracking in 304 and 316 stainless steels are often better managed with AL-6XN alloy. This alloy is resistant to corrosion from various acids, salt solutions (sodium chloride) in hot and cold environments.

Heat Treatment

If necessary, AL-6XN alloy is annealed after heavy cold work 2050-2150°F (1121-1177C), water quench. Slow cooling is not recommended, as this would reduce the alloy’s corrosion resistance.

WELDING

All methods except oxyacetylene welding have been successfully used with this alloy. While a filler metal of type 316 stainless may be sufficient for some applications, it is preferable to employ a higher alloy such as 625, or C-276 for maximum performance.

What are the characteristics of AL-6XN?

· Excellent resistance to pitting and crevice corrosion in chloride solutions

· Practical immunity to stress corrosion in NaCl environments

· High Strength and toughness

Available Forms

We provide you with a variety of product forms, including but not limited to

● Bar & Rod

● Pipe & Tube

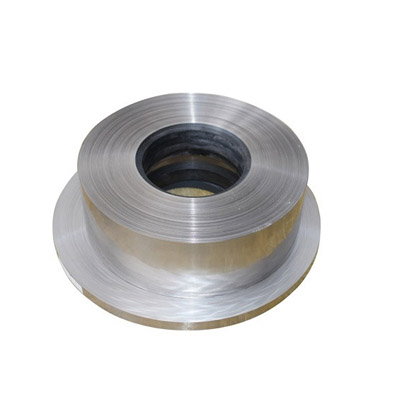

● Coil & Strip

● Plate & Sheet & Circle

● Wire & Welding

● Fitting (Flange, Elbow, Tee...)

● Customize

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder