17-7PH SUS 631/W.Nr:1.4568 stainless steel

Overview

17-7 PH is a precipitation-hardening stainless steel which combines high strength and hardness.

The alloy has excellent fatigue properties, good corrosion resistance and is easily formed. Due to the alloys good mechanical and physical properties, 17-7PH is particularly popular in the aerospace sector. The alloy can be used in the manufacture of flat springs up to 315°C (600°F).

17-7PH Precipitation Hardening Alloy is a semi-austenitic stainless steel which is austenitic in the annealed condition, but martensitic in the hardened condition. 17-7PH provides high strength and hardness, excellent fatigue properties, good corrosion resistance and minimum distortion upon heat treatment. It is easily formed in the annealed condition, then hardened to high strength levels by simple heat treatments to Conditions RH 950 and TH 1050. The exceptionally high strength of Condition CH 900 offers many advantages where limited ductility and workability are permissible. In its heat treated condition, this alloy provides exceptional mechanical properties at temperatures up to 900 °F (482 °C).

Limiting Chemical Composition, %

Iron.......................................................................................................................................................................................70.59-76.75

Nickel..........................................................................................................................................................................................6.5-7.75

Chromium............................................................................................................................................................................16.00-18.00

Manganese...............................................................................................................................................................................1.00 max.

Carbon.......................................................................................................................................................................................0.09 max.

Silicon........................................................................................................................................................................................1.00 max.

Sulphur.......................................................................................................................................................................................0.03 max.

Phosphorus...............................................................................................................................................................................0.04 max.

Aluminium.................................................................................................................................................................................0.75-1.50

Physical properties

Properties |

Metric |

Imperial |

Density |

7.80 g/cm³ |

0.282 lb/in³ |

Mechanical Properties

Properties |

Tensile strength |

Yield strength |

Modulus of elasticity |

Poisson's ratio |

Elongation at break |

Hardness,Rockwell C |

Metric |

1170 MPa |

965 MPa |

204 GPa |

0.27-0.30 |

6% |

38 |

Imperial |

170000 psi |

140000 psi |

29600 ksi |

0.27-0.30 |

6% |

38 |

Corrosion resistance

17-7PH stainless steel is a precipitation-hardened stainless steel alloy with excellent corrosion resistance for a variety of applications requiring high performance materials.

Its corrosion resistance under all heat treatment conditions is the same as that of other stainless steel types, and surface rust can occur in some environments. For example, in the Marine environment, stainless steel will show signs of rust after a relatively short exposure time. However, after a year or two of exposure, the amount of rust is hardly more than the amount of rust after six months. Like all martensitic stainless steels, 17-7PH stainless steels may crack under stress environments containing hydrogen sulfide and are therefore not recommended for use in such applications.

In addition, because 17-7PH stainless steel contains aluminum, it also has a good stress cracking resistance, suitable for a variety of high temperature and high stress environments. At the same time, it also has good plasticity and hardening ability, can control hardness through heat treatment, and can carry out a variety of cold working and hot working processes. In terms of welding, 17-7PH stainless steel has good weldability in conventional welding, high-frequency induction welding and arc welding.

Heat treatment

For heat treating stainless steel grade 17-7 PH, three important steps need to be carried out – austenite conditioning, cooling to transform the austenite to martensite, and precipitation hardening to condition TH 1050 or RH 950.

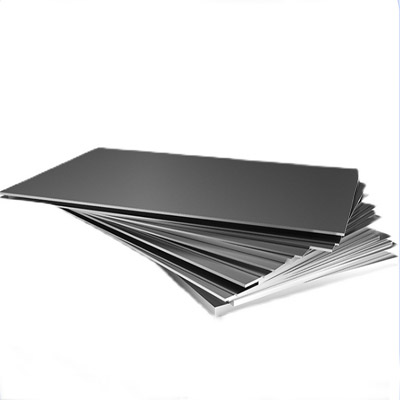

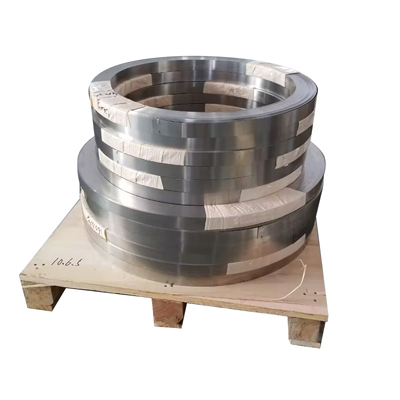

Available Forms

We provide you with a variety of product forms, including but not limited to

● Bar & Rod

● Pipe & Tube

● Coil & Strip

● Plate & Sheet & Circle

● Wire & Welding

● Fitting (Flange, Elbow, Tee...)

● Customize

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder