17-4PH UNS S17400/W.Nr:1.4542 stainless steel

Overview

Alloy 17-4PH (UNS S17400), Type630, is a chromium-nickel-copper precipitation-hardening martensitic stainless steel with an addition of niobium. 17-4PH combines high strength and hardness with good corrosion resistance.

The alloy is furnished in the solution annealed condition(Condition A). It should not be used at temperatures above 572°F (300°C)or for cryogenic service. Optimal mechanical properties can be obtained by subjecting the alloy to age hardening heat treatments. Heat treatment in the 900°F (482°C) range produces the highest strength.

The corrosion resistance of Alloy17-4PH is comparable to 304stainless steel in most environments,and is generally superior to the 400series stainless steels. It is used in applications where the combination of moderate corrosion resistance and unusually high strength are required.Alloy 17-4PH can be easily welded and processed by standard shop fabrication practices. It is magnetic.

Limiting Chemical Composition, %

Iron..............................................................................................................................................................................................69.91-78.85

Nickel...............................................................................................................................................................................................3.00-5.00

Chromium...................................................................................................................................................................................15.00-17.50

Copper.............................................................................................................................................................................................3.00-5.00

Manganese.....................................................................................................................................................................................1.00 max.

Carbon.............................................................................................................................................................................................0.07 max.

Silicon..............................................................................................................................................................................................1.00 max.

Sulphur.............................................................................................................................................................................................0.03 max.

Phosphorus......................................................................................................................................................................................0.04 max.

Niobium plus Tantalum...................................................................................................................................................................0.15-0.45

Physical properties

Density |

Modulus of Elasticity |

Thermal Conductivity |

Specific Heat |

Melting Range |

7.75 g/cm³ |

196 GPa |

18.3 W/m.K |

460 J/kg-°C |

1404 – 1440°C |

Mechanical Properties

Condition |

Tensile Strength (MPa) |

Yield strength |

Modulus of elasticity |

Hardness Brinell (HB) |

Solution Treated |

1105 typ |

1000 typ |

15 typ |

363 max |

Condition 900 |

1310 min |

1170 min |

10 min |

388 min |

Condition 1150 |

930 min |

724 min |

16 min |

277 min |

Corrosion resistance

The corrosion resistance of Alloy 17-4PH is comparable to 304 stainless steel in most environments, and is generally superior to the 400 series stainless steels. It is used in applications where the combination of moderate corrosion resistance and unusually high strength are required. Alloy 17-4PHhas corrosion resistance comparable to 304L in some chemical, dairy, food,paper and petroleum applications.Alloy 17-4PH in the solution-annealed condition should not generally be put in service. The alloy is subject to brittle fractures and more sensitive to chloride stress corrosion cracking than the aged material.If risks of chloride stress corrosion cracking are present the higher aging temperatures should be selected over 1022°F (550°C), preferably 1094°F(590°C). 1022°F (550°C) is the recommended tempering temperature in chloride service. 1094°F (590°C) is preferred in H2S media.Alloy 17-4PH is subject to crevice corrosion and pitting attack when exposed to stagnant seawater for a duration of time.

Heat treatment

Solution treatment — Grade 630 stainless steels are heated at 1040°C for 0.5 h, then air-cooled to 30°C. Small sections of these grades can be oil quenched.

Hardening — Grade 630 stainless steels are age-hardened at low temperatures to achieve the required mechanical properties. During the process, superficial discoloration occurs followed by shrinkage at 0.10% for condition H1150, and 0.05% for condition H900.

The table below shows the typical mechanical properties of grade 630 steels after solution treatment and age hardening:

Cond. |

Temp(C) |

Time (h) |

Typical Hardness Rockwell C |

Tensile Strength (MPa) |

A |

Ann |

36 |

1100 |

|

H900 |

482 |

1 |

44 |

- |

H925 |

496 |

4 |

42 |

1170-1320 |

H1025 |

552 |

4 |

38 |

1070-1220 |

H1075 |

580 |

4 |

36 |

1000-1150 |

H1100 |

593 |

4 |

35 |

970-1120 |

H1150 |

621 |

4 |

33 |

930-1080 |

Available Forms

We provide you with a variety of product forms, including but not limited to

● Bar & Rod

● Pipe & Tube

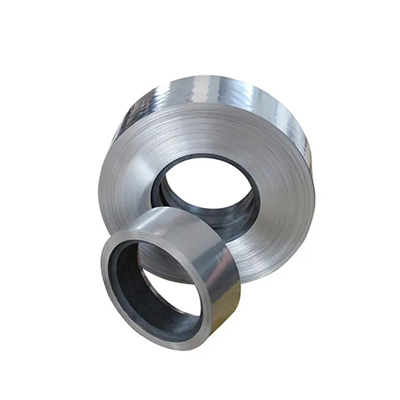

● Coil & Strip

● Plate & Sheet & Circle

● Wire & Welding

● Fitting (Flange, Elbow, Tee...)

● Customize

description2

Inconel 625

Inconel 625 Inconel 718

Inconel 718 Inconel 725

Inconel 725 Inconel X-750

Inconel X-750 Inconel 690

Inconel 690 Inconel 617

Inconel 617 Inconel 601

Inconel 601 Inconel 600

Inconel 600 Inconel 686

Inconel 686 Inconel 602CA

Inconel 602CA Incoloy A-286

Incoloy A-286 Incoloy 825

Incoloy 825 Incoloy 925

Incoloy 925 Incoloy 926

Incoloy 926 Incoloy 800

Incoloy 800 Incoloy 800H

Incoloy 800H Incoloy 800HT

Incoloy 800HT Incoloy 909

Incoloy 909 Incoloy 31

Incoloy 31 Incoloy 901

Incoloy 901 Monel K-500

Monel K-500 Monel 400

Monel 400 Nimonic 263

Nimonic 263 Nimonic 75

Nimonic 75 Nimonic 80A

Nimonic 80A Nimonic 90

Nimonic 90 Nimonic PE11

Nimonic PE11 Nimonic PE16

Nimonic PE16 Nimonic PK33

Nimonic PK33 Nimonic 901

Nimonic 901 Nimonic 81

Nimonic 81 Nimonic 86

Nimonic 86 Nimonic 105

Nimonic 105 Nimonic 115

Nimonic 115 Hastelloy C-276

Hastelloy C-276 Hastelloy C

Hastelloy C Hastelloy C4

Hastelloy C4 Hastelloy C-22

Hastelloy C-22 Hastelloy C-2000

Hastelloy C-2000 Hastelloy B-2

Hastelloy B-2 Hastelloy B-3

Hastelloy B-3 Hastelloy G30

Hastelloy G30 Hastelloy X

Hastelloy X Super Invar 32-5(4J32)

Super Invar 32-5(4J32) Alloy 36(4J36)

Alloy 36(4J36) Alloy 42(4J42)

Alloy 42(4J42) Alloy 50(1J50)

Alloy 50(1J50) Hiperco 50(1J22)

Hiperco 50(1J22) Alloy 46

Alloy 46 Permalloy (1J79)

Permalloy (1J79) Supermalloy(1J85)

Supermalloy(1J85) ERNiCrMo-2

ERNiCrMo-2 ERNiCrMo-3

ERNiCrMo-3 ERNiCrMo-4

ERNiCrMo-4 ERNiCrFe-7

ERNiCrFe-7 ERNiCrFe-7A

ERNiCrFe-7A ERNiCrMo-10

ERNiCrMo-10 ERNiCrCoMo-1

ERNiCrCoMo-1 ERNiFeCr-2

ERNiFeCr-2 ERNiFeCr-1

ERNiFeCr-1 ERNiMo-8

ERNiMo-8 ERNiCrMo-13

ERNiCrMo-13 ERNiCr-4

ERNiCr-4 ERNiCr-3

ERNiCr-3 ERNi-1

ERNi-1 Haynes-25

Haynes-25 Hayness-188

Hayness-188 MP35N

MP35N Refractory 26

Refractory 26 Waspaloy alloy

Waspaloy alloy 17-4PH

17-4PH 17-7PH

17-7PH 904L

904L Nitronic 50

Nitronic 50 Nitronic 60

Nitronic 60 AL-6XN

AL-6XN F55

F55 PH 13-8

PH 13-8 Haynes-230

Haynes-230 Nickel 200

Nickel 200 Cr20Ni80

Cr20Ni80 Sheet & Plate

Sheet & Plate Strip & Foil

Strip & Foil Bar & Rod

Bar & Rod Pipe & Tube

Pipe & Tube Bolts & Fasteners

Bolts & Fasteners Flange & Ring

Flange & Ring Nickel Alloy Powder

Nickel Alloy Powder